Dynamic Simulation for Optimized Production

Ensure safety and reliability across your operations with expert-driven solutions and advanced dynamic process modeling.

Enhancing safety without compromizing efficiency

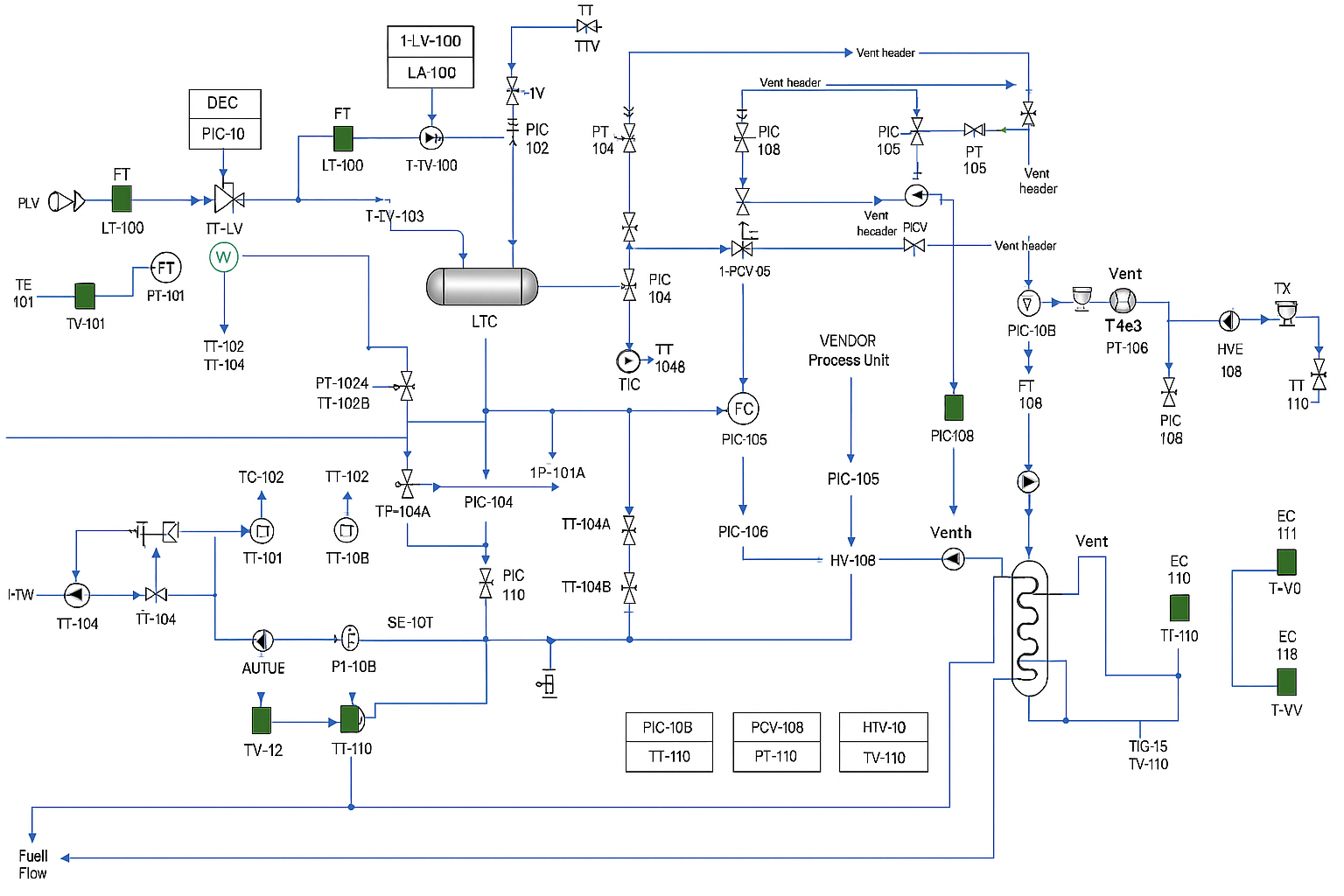

Our Process Safety services are designed to enhance your facility’s safety, optimize performance, and reduce operational risks. With expertise in thermodynamics, dynamic simulations, and relief system design, we provide targeted evaluations and customized recommendations. From refinery reactors to gas injection networks, we ensure your operations are safe, efficient, and compliant with industry standards.

Safe solutions for complex systems

- Automatic generation of PSV calculation sheets and datasheets

- Pressure Safety Valve (PSV) sizing and rating using conventional methods or dynamic simulation

- Calculation of relief flows and conditions under various scenarios

- Sizing and rating of PSV orifice areas

- Dynamic relief analysis of distillation columns and complex systems

- Review of relief scenarios, including quantitative risk assessments (QRA)

- Flare system hydraulics analysis (backpressure, Mach number, system constraints)

- Evaluation of flare system alternatives, such as crossovers and flare recovery units (FRUs)

- Flare stack design support, including radiation zone calculations and inputs for dispersion modelling

- Development of high-fidelity digital twins for dynamic simulation

- Analysis of compressor start-up, shutdown, and emergency shutdown scenarios

- Controller tuning and optimization for stable process control

- Flow assurance evaluations to prevent hydrate formation, slugging, and blockages

- Simulation of rupture events, including determination of minimum metal wall temperatures (MMWT)

- Blowdown analysis for compressors, pipelines, and gas injection systems

- Sizing and rating of rupture disks

- Evaluation of blowdown scenarios for emergency preparedness and response

Ensure your facility operates reliably with evaluations of key systems such as compressors, relief networks, and distillation columns.

Identify and address operational and environmental risks through advanced safety modelling and customized recommendations.

Leverage expertise in thermodynamics and process design to create tailored safety solutions.

Maintain compliance and operational reliability with continuous process safety evaluations and recommendations.

Double-Pipe Heat Exchanger Design: A Step-by-Step Guide

Double-pipe heat exchangers are essential in chemical process design, maximizing energy efficiency in industries like oil & gas, food, and HVAC. Explore step-by-step guidance for calculating duty, surface area, heat transfer, and more to optimize performance and design the right heat exchanger for your needs.

Risks of Blending Hydrogen and Methane

Blending hydrogen with methane? Understand the thermodynamic behaviors, like hydrogen's negative Joule-Thomson effect and excess enthalpy, for better process efficiency and design.

Safety Issues When Blending Hydrogen with Natural Gas

Blending hydrogen with natural gas aids decarbonization but poses safety risks like embrittlement and leakage. Follow best practices for safe, efficient integration.

Expertise to safeguard your operations

Learn how our core pillars support our service offerings.

Engineering

- Extensive process modelling expertise

- Dynamic simulations for optimal production

- In compliance with API standards and HAZOP

Sustainability

- Minimize risk of potential emergency scenarios and environmental impacts

- Ensure sustainability and ESG compliance

Innovation

- Cutting-edge dynamic process simulations

- Advanced assessment and analysis capabilities

Explore other services

Digital Transformations

Empowering operational excellence through digitalization

Strategic Advice

Expert solutions for industry challenges, tailored to you

Regulatory Compliance

Streamlined emissions management and reporting service