Leaders in Advanced Process Modelling and Engineering

Streamline your operations with data-driven recommendations that will maximize performance, reduce costs, and enhance sustainability.

Process optimization powered by high-fidelity simulation models

Achieving operational efficiency in oil and gas demands precision and innovation. Our Process Optimization service is founded in industry-leading dynamic simulation and engineering expertise to help you solve complex challenges, maximize production, and reduce costs. From troubleshooting to energy efficiency, we provide tailored optimization solutions to meet your goals.

Advanced solutions, no matter the complexity

- Pre-FEED evaluations

- Rigorous heat exchanger rating

- Compressor train cooling strategy

- Identifying process constraints and reliability improvements

- Evaluating new technologies (e.g., CCS, hydrogen blending, alternative configurations)

- Flow assurance and hydraulic evaluations

- Slug volume prediction

- Distillation column flooding and flow regime analysis

- Oil refinery processes (CDU, VDU, FCC, etc.)

- Oil batteries, pipelines, and heat exchanger networks

- Gas sweetening and CCS solutions

- SAGD and bitumen upgrader optimization

- Bitumen value chain (SAGD upgrading, refining)

- Natural gas value chain (well gathering systems, processing, transmission)

- Lifecycle analysis to assess environmental impacts

- Pinch analysis and heat recovery

- Combustion optimization

- Electrification strategies to minimize environmental footprints

Identify and implement improvements that reduce costs, optimize production, and minimize downtime.

Leverage advanced simulations and process models for clear, actionable insights into operational strategies.

Tackle process constraints and troubleshoot issues with tailored engineering solutions, ensuring productivity and uptime.

Reduce energy consumption and operational costs with sustainable, efficient solutions tailored to your facility.

Rely on our technical expertise to solve your facility’s unique challenges with optimized designs and strategies.

Achieve your environmental goals with solutions designed to reduce emissions and energy consumption while maintaining operational excellence.

Advanced Process Intelligence

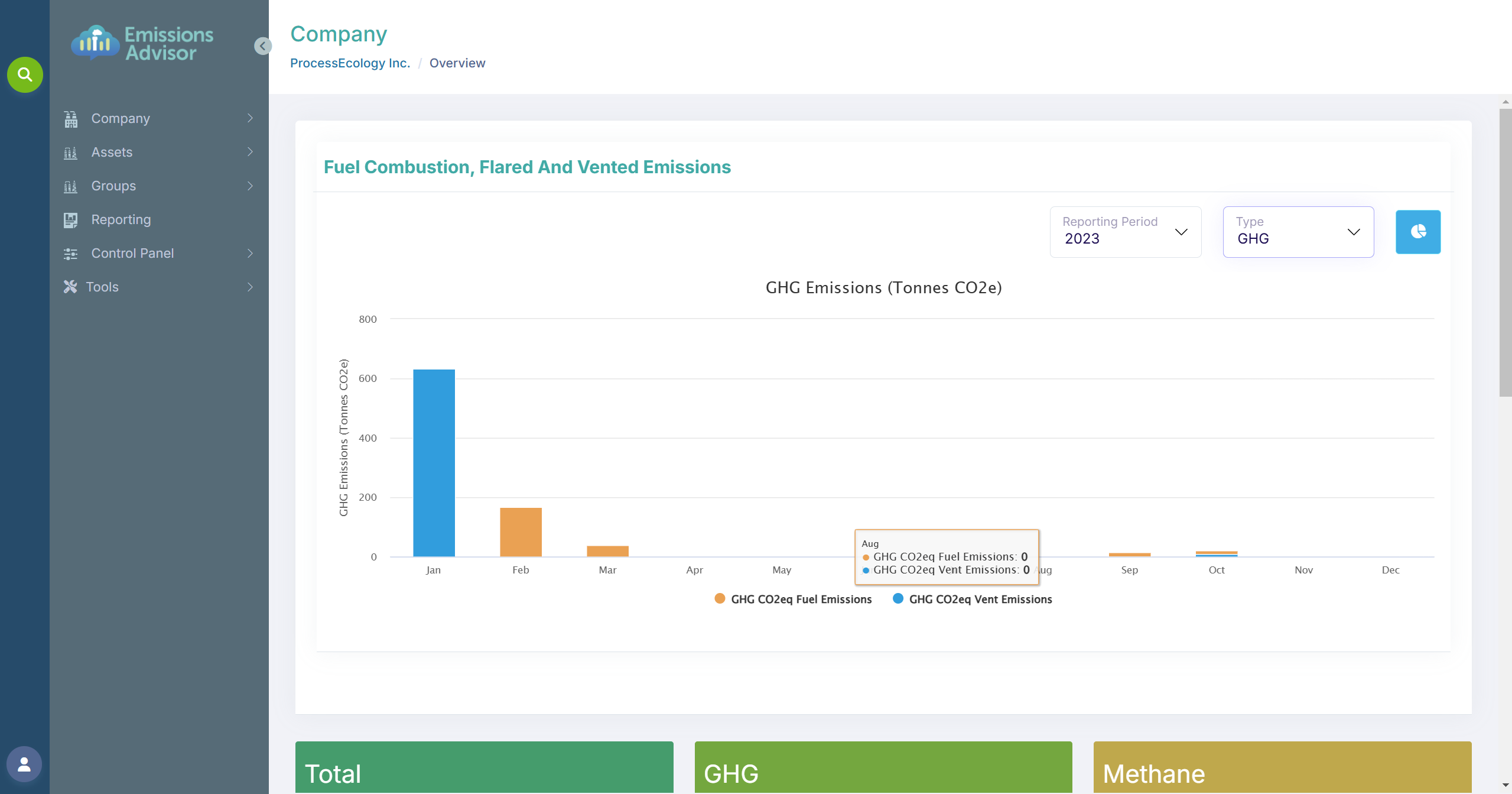

XTREMA is a comprehensive process intelligence technology that provides a realtime, holistic view of oil and gas operations by integrating top-down sensor data with bottom-up facility data for optimal performance, emissions tracking, and operational efficiency.

GHG Reduction in SAGD Operations with Pinch Analysis

Explore how Pinch Analysis boosts SAGD efficiency by reducing GHG emissions, improving heat recovery, and cutting fuel costs in oil production

Reducing Diluent Cost in Dilbit Preparation

Discover cost-effective strategies for reducing diluent expenses in Dilbit preparation by optimizing butane blending while meeting viscosity and vapor pressure constraints.

Estimating Heat Losses in Heavy Oil Pipelines

Learn how to accurately estimate heat losses in heavy oil pipelines with a first-principles model to optimize operations and prevent costly disruptions in harsh conditions.

Your partners in optimization

Learn how our core pillars support our service offerings.

Engineering

- 100+ years combined experience in process modelling

- Leverage advanced tools and dynamic simulation models

- Provides the most accurate emissions data

Sustainability

- Prioritization of energy efficiency and sustainable practices

- Advanced environmental impact assessments

- Identify opportunities for operational emissions reductions

Innovation

- Integration with advanced simulation tools, algorithms and machine learning technologies

- Future-proof solutions for complex challenges

- Streamlined systems optimization

Explore other services

Energy Transition

Innovative approaches to achieve low-carbon operations

Process Safety

Enhancing safety without compromising efficiency

Digital Transformations

Empowering operational excellence through digitalization

If you’re looking to enhance the sustainability of your operations, check our Energy Transition offering to learn how we can work with you to recommend emissions reduction strategies and develop comprehensive mitigation roadmaps.